Precise Mechanism & Ergonomic Design

Precise Mechanism & Ergonomic Design

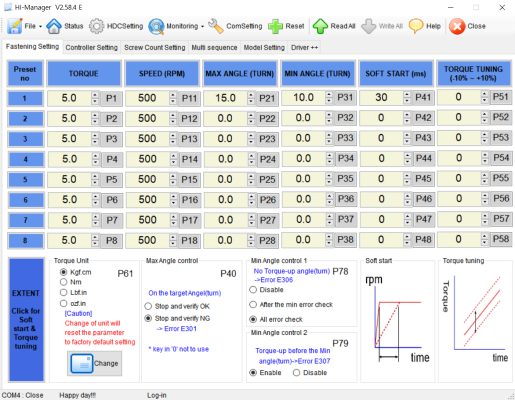

· Up to 8 different torque, speed and angle(Min/Max) presets savable to the memory

· Each presets can be saved and chosen easily by the operator or sensors

· Easy manual or automatic torque change

· High efficiency is acheived by high speed

· Error proof system by tightening quality monitoring and screw counting function

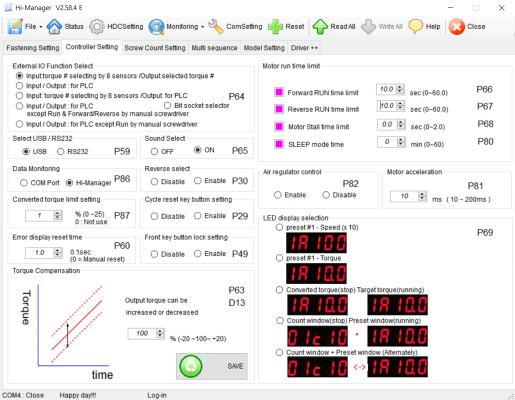

· Tightening data management by serial communication with PC and PLC

· Quick recognition of errors by displaying error codes

· Changes RPM automatically when torque is changed(manual setting available)

· Tightening data check by RS232C and USB communication

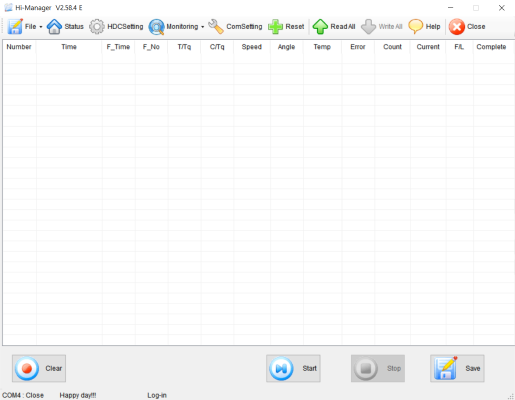

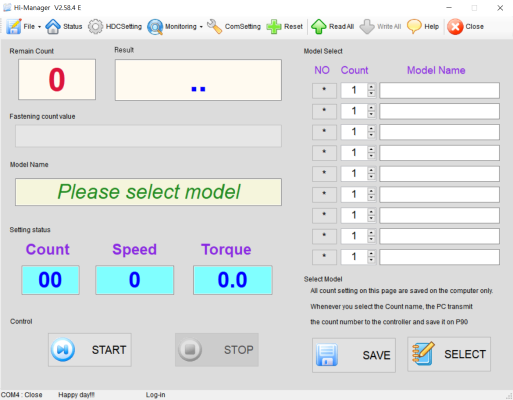

· Real time data monitoring and simple configuration by Hi-Manager(PC software)

· Firmware upgrade by serial port

Model | Start | Torque Unit | Speed | Weight | Bit Type | Paired Controller | ||

[Kgf.cm] | [rpm] | [kg] | ||||||

Min | Max | Min | Max | |||||

HD35N | LEVER | 12 | 35 | 500 | 1,500 | 0.7 | A, B | HDC-35i |

HD50N | 15 | 50 | 300 | 1,000 | 0.7 | A, B | ||

HD100N | 30 | 100 | 100 | 500 | 0.75 | A | ||

HD35NP | PUSH | 12 | 35 | 500 | 1,500 | 0.7 | A, B | HDC-35i |

HD50NP | 15 | 50 | 300 | 1,050 | 0.7 | A, B | ||

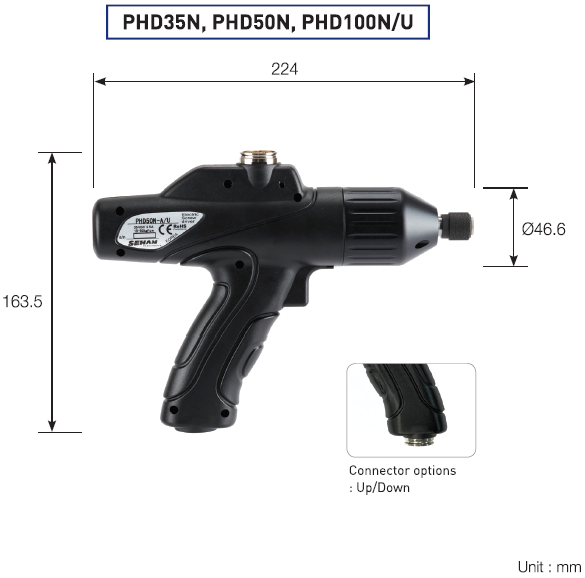

PHD35N | PISTOL | 12 | 35 | 500 | 1,500 | 0.82 | A, B | HDC-35i |

PHD50N | 15 | 50 | 300 | 1,000 | 0.82 | A, B | ||

PHD100N | 30 | 100 | 250 | 500 | 0.82 | A | ||

[BIT TYPE]

[14PIN QUICK CHANGE ROBOT CABLE]

NO | Item | Specification |

1 | Rated Input | AC120VC or AC220V, 50~60Hz, 2.5A |

2 | Rated Output | DC35V, 4A |

3 | Torque | 12 ~ 100 [Kgf.cm] |

4 | Speed | 300 ~ 1,500 [rpm] |

5 | Angle | 0.1 ~ 30 |

6 | Torque calibration | -20% ~ +20% |

7 | Operating environment | 0 ~ 40℃ / 15 ~ 80% RH ( without dew ) |

8 | Input air pressure (bar) | min 4.5 bar / max 6 bar |

9 | Preset parameters | Torque, (Speed) & Angle |

10 | Preset # selecting |

|

11 | Screwdriver Info Recognition | Automatic recognition and correction by screwdriver's EEP Rom |

12 | Error Info Display | Divided into system, communication and pattern errors and displayed as codes |

13 | Tightening Quality Monitoring | OK/NG judgement by monitoring tightening time, turns etc. |

14 | Screw Counter | Save up to 8 different models, monitor OK tighteing counts |

15 | Monitoring Parameter Setting | Tightening data monitoring and parameter setting is possible by Smart Manager |

[HI Manager]

- Fastening Setting - Controller Setting

- Real Time Monitoring - Screwcounter Monitoring

| No. | Title | Write | Date | Hit | ||||

|---|---|---|---|---|---|---|---|---|

| No posts have been submitted. | ||||||||